QUALITY EQUIPMENTS FOR A SUSTAINABLE STEAM SYSTEM

Lalonde Systhermique team works with the best parts and equipments available on the industrial market. When existing products do not meet our standards of performance, reliability and durability, we design and manufacture customized equipment.

The role of a steam trap is to prevent steam from escaping in order to maintain the pressure in the heat exchanger while purging the condensate produced by this exchanger. In most cases, the pressure changes from the operating value (before the steam trap) to almost atmospheric pressure (after the steam trap).

The team members of Lalonde Systhermique require that the equipment installed in our work must meet the requirements for optimal and long-term economy. The choice of our steam traps is based on these criteria:

- Savings in Energy cost and Investment

- Condensate discharge without loss of steam

- Automatic evacuation of uncondensable gases

- Should not affect the heating process

- Fully use the latent heat before the steam trap

- Not affected by pressure

- Suitable for pressure and flow fluctuations

- Easy Installation

- Resistant to corrosion

- Resistant to dirt

- Easy maintenance

- Freeze Protection

- Resistant to water hammer

Back Pressure

When the pressure at the outlet of the steam trap is higher than the atmospheric pressure, we say that there is a back pressure. This back pressure can have different sources. For example, it can come from the condensate that we want to push into a rising pipe or, again, it can come from the expansion steam. There is always a back pressure (a pressure in the opposite direction to the flow) to be controlled so that the condensate can flow through the steam trap. It is necessary for the operating pressure before the trap to be greater than the back pressure.

Differential pressure as driving force

The pressure difference between the two sides of a steam trap (called differential pressure ) is the driving force allowing the liquid to flow through this equipment. A sufficient differential pressure between the two sides of a steam trap is required for the condensate to pass through. If the differential pressure becomes too low, this may result in accumulation in the unit.

While a small differential pressure is sufficient to ensure flow through some steam traps, other models require a much larger differential pressure to operate properly. It is important to know the characteristics of the steam traps and the steam system. The large difference in pressure that we find in the vast majority of steam systems is sufficient to push the condensate from its point of origin to a tank without using an electric pump. This is one of the basic principles of the Steam Condensate Closed System.

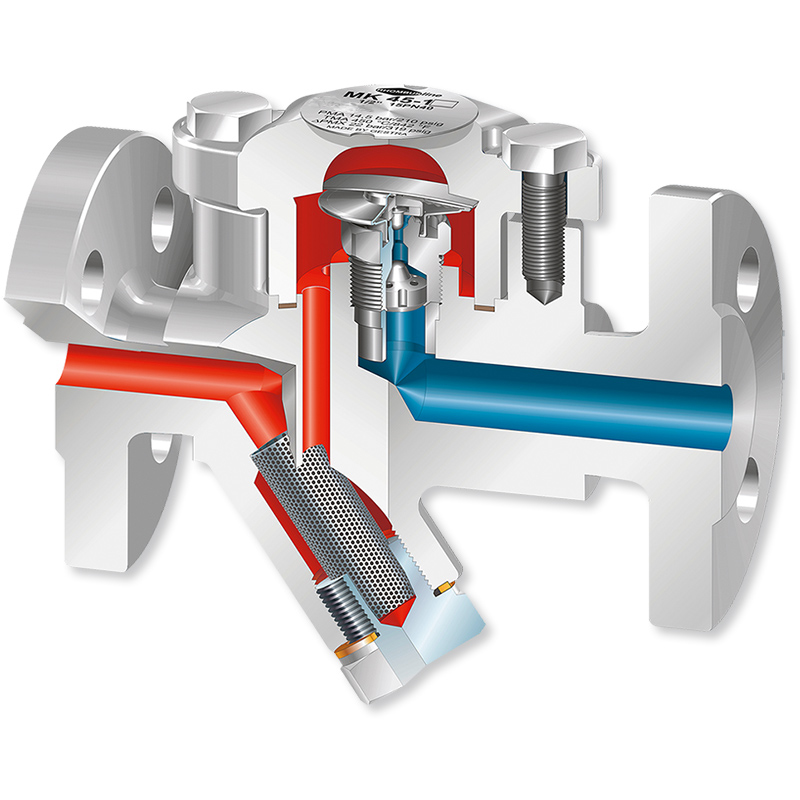

Self-Regulating Membrane Thermal Steam Trap

The self-regulating diaphragm thermal trap has as its main operating element: a metal membrane filled with a mixture of alcohol and water. The diaphragm contracts when it comes in contact with condensate and relaxes in the presence of steam. When the amount of condensate is large, the membrane remains contracted so as to allow a continuous flow of condensate. In the presence of steam, the membrane closes. There are moments when the steam trap operates in continuous flow, when it operates intermittently (opening and closing under the influence of the temperature of the condensate) and other times when it is completely closed. The steam trap automatically adjusts to pressure variations.

The self-regulating membrane thermal trap does not react as a function of the amount of condensate formed, but depends on the temperature of the condensate, which is an indirect measure of the amount of condensate formed. Indeed, the formation of condensate increases with the increase of the load of an apparatus. The greater the load of the appliance, the more condensate is formed. The temperature then decreases and the trap opens. The lower the load of the appliance, the more the condensate will get hot in small quantities to the trap and the more the trap is closed. There is no risk of accumulation, since the opening of the trap valve adjusts very quickly and precisely to the amount of condensate produced.

There are different models of capsules for different applications depending the operating temperatures. In cases where the quantity of condensate produced is greater than the capacity of a single capsule, it is sufficient to use a model that uses more than one capsule. It is possible to install up to 9 capsules on a steam trap in order to obtain maximum condensation removal capacities with minimum space.

Automatic deaeration

All self-regulating diaphragm steam traps allow automatic deaeration. This is due to the fact that the increase amount of air in the steam reduces the temperature without pressure drop. As the membrane of the trap reacts to the temperature, it opens to let the gas escape. This is an important advantage of this type of steam trap compared to other types.

Effects of pressure on self-regulating membrane steam trap

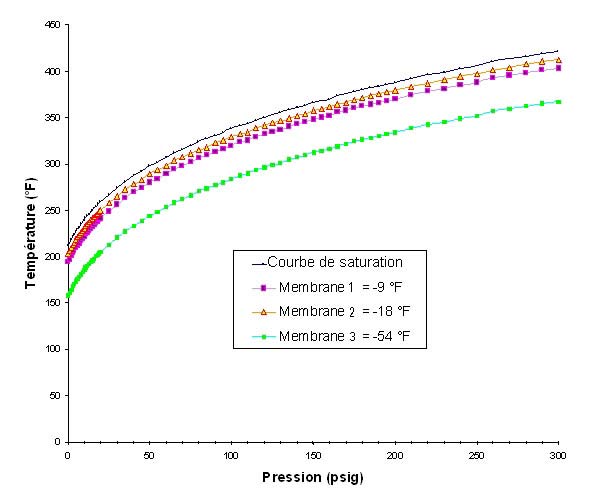

Depending on the membrane used, the condensate temperature is 9 oF (5 oC), 18 oF (10 oC) and 54 oF (30 oC), respectively, under the saturated steam temperature, regardless of operating pressure (0 - 320 psig). In fact, the curves of opening and closing of the membrane are adapted to the saturation curve so that the nominal temperature difference required to open and close the steam trap is almost the same over the entire range of operating pressures. The following figure shows a saturation curve, as well as the opening and closing curves of the three membranes.

A universal steam trap?

This type of steam trap is therefore universal in the sense that it can purge a considerable range of condensate flow rates over a wide range of operating pressures. The opening and closing curves of this trap are perfectly adapted to the saturation curve of the steam over the entire operating pressure range. The small volume of fluid, as well as the large contact surface of the membrane, ensures a rapid response to the slightest temperature fluctuations in the condensate. This type of steam trap can be used with heat exchangers of all sizes. It allows automatic deaeration and is not affected by back pressure or corrosion.

In addition, this steam trap is compact, which greatly facilitates its handling and allows installation in restricted areas. It can be installed in any direction. The parts are always the same, regardless of model and throughput, which simplifies inventory management and maintenance. The Self-Regulating Membrane Thermal Traps used by Lalonde & nbsp; Systhermique are unmatched in terms of quality and precision of operation.