Steam Condensate Closed System®

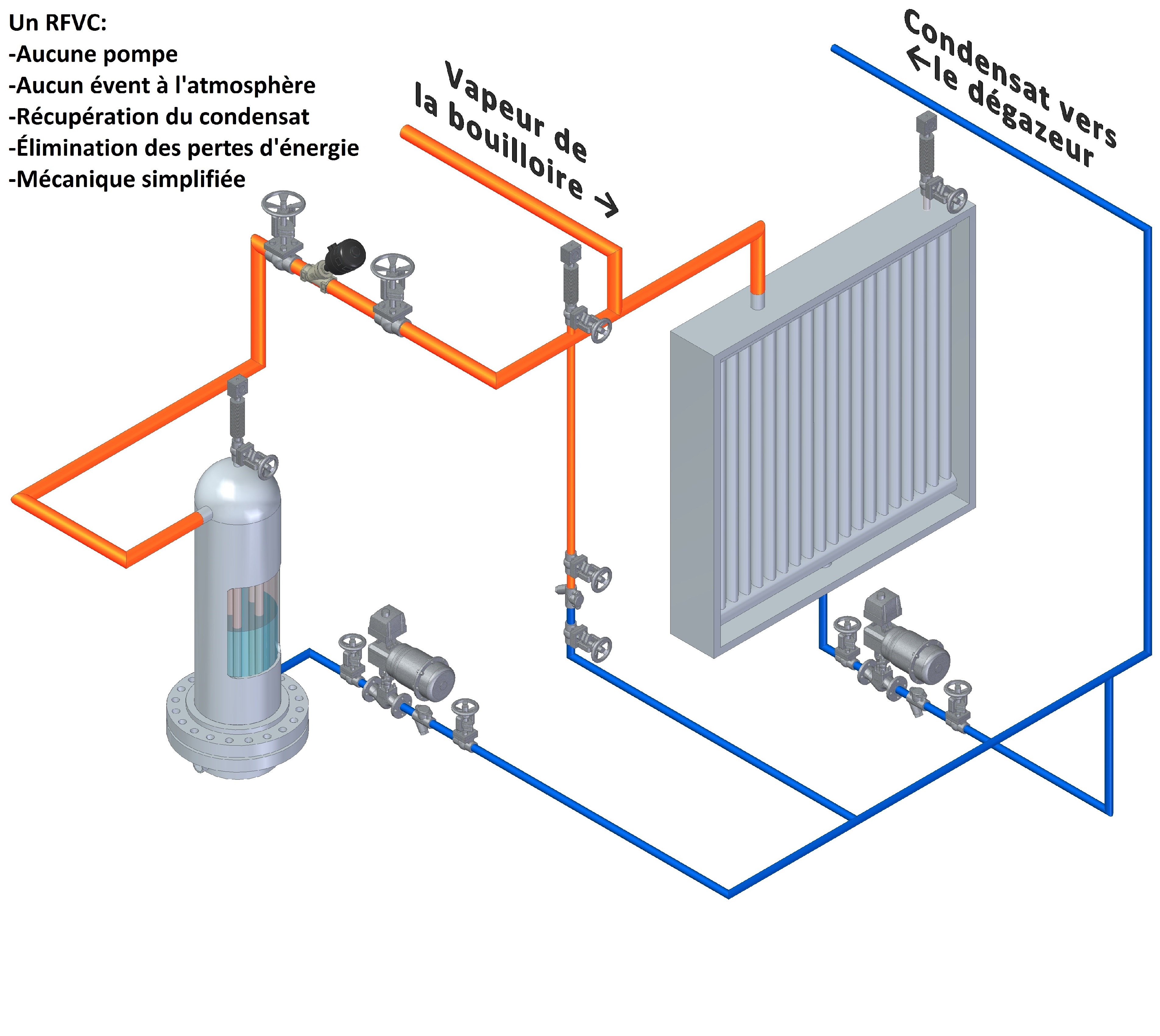

SCCS® is a global and optimized solution for steam transportation, control and use. In a conventional steam system, the hot condensate that comes out of heat exchangers is directed to a flash tank that vents away the surplus energy from the condensate. The condensate’s energy can amounts to 20% of the steam system’s total energy. That energy had to be paid for! A Lalonde Systhermique SCCS® allows the condensate to be returned to the boiler under controlled pressure, without any pump or energy loss: all of the flash steam’s energy is recovered.

In a SCCS®, noncondensable gases are eliminated throughout the whole system. This decreases corrosion in equipments and increases heat transfers.

Finally, a SCCS® is a series of interventions aiming at a more reliable and efficient steam system. The system is entirely rethought in order to provide optimal precision and efficiency. Converting conventional steam systems into closed systems is recommended by the Office of energy efficiency of Canada.

Read their PDF publication.

Mechanical Advantages

- Elimination of water hammer

- Drastic decrease of corrosion

- Better heat transfer

- Stable Steam Pressure

- More reliable and durable heat exchangers (with 0.5 oF precision)

- System can be automated (automatic stops/starts)

- Steam Coils for 100% make-up air can be used with no risk of freezing and without dampers

Environmental Advantages

- Reduced greenhouse gas emissions (around 20%, depending on process needs)

- Reduced consumption of water-treatment chemicals (95% and more)

- Reduced water consumption – no make-up water is required

Financial Advantages

- Reduced fuel costs (around 20%, depending on process needs)

- Increased production

- Payback period of 3 years or less

- Reduced consumption of water-treatment chemicals (up to 95%)

- Reduced mechanical maintenance costs

- Reduced cost of equipments (by 50%)

- Increased useful lifespan of equipments (400%)

.jpg)